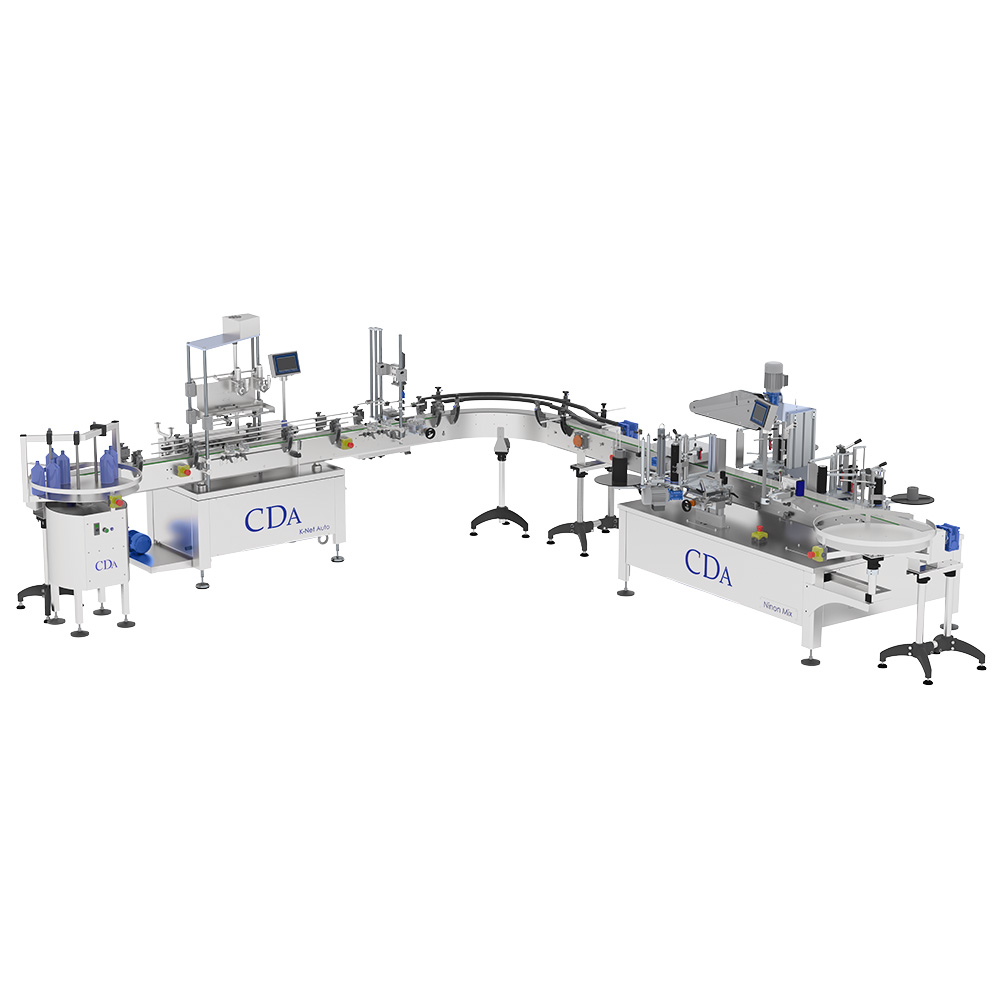

Complete line – K Net Auto – VS400 – Ninon Mix K Net Auto + VS 400 + Ninon Mix

CDA designs complete packaging lines to combine filling, capping and labeling in one place.

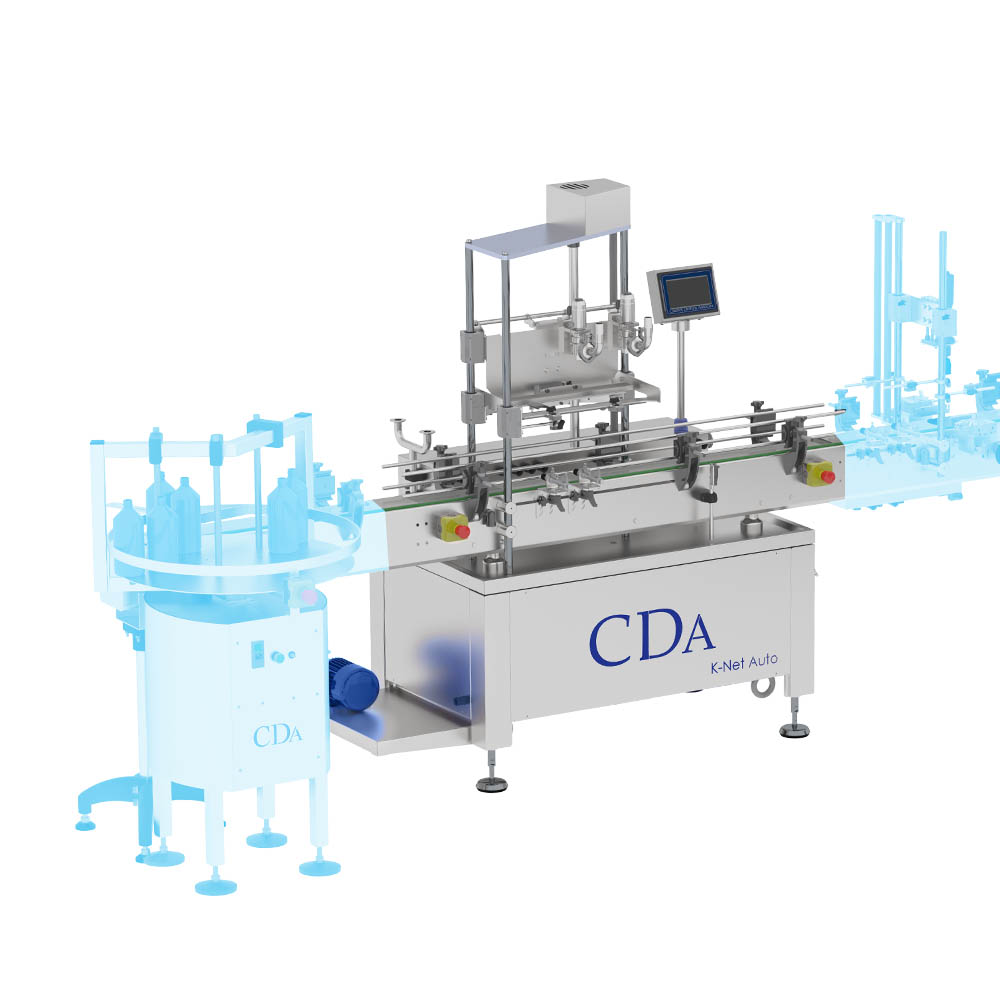

The filling stage on this line is carried out by the K-Net Auto. This auto filler is equipped with a dosing system that can be adapted (peristaltic, flowmeter, volumetric, etc.) according to the sector of activity and the product range. It allows the filling of up to 1200 products per hour, i.e. 20 products per minute with a precision of +/- 0.5% of the dosed liquid.

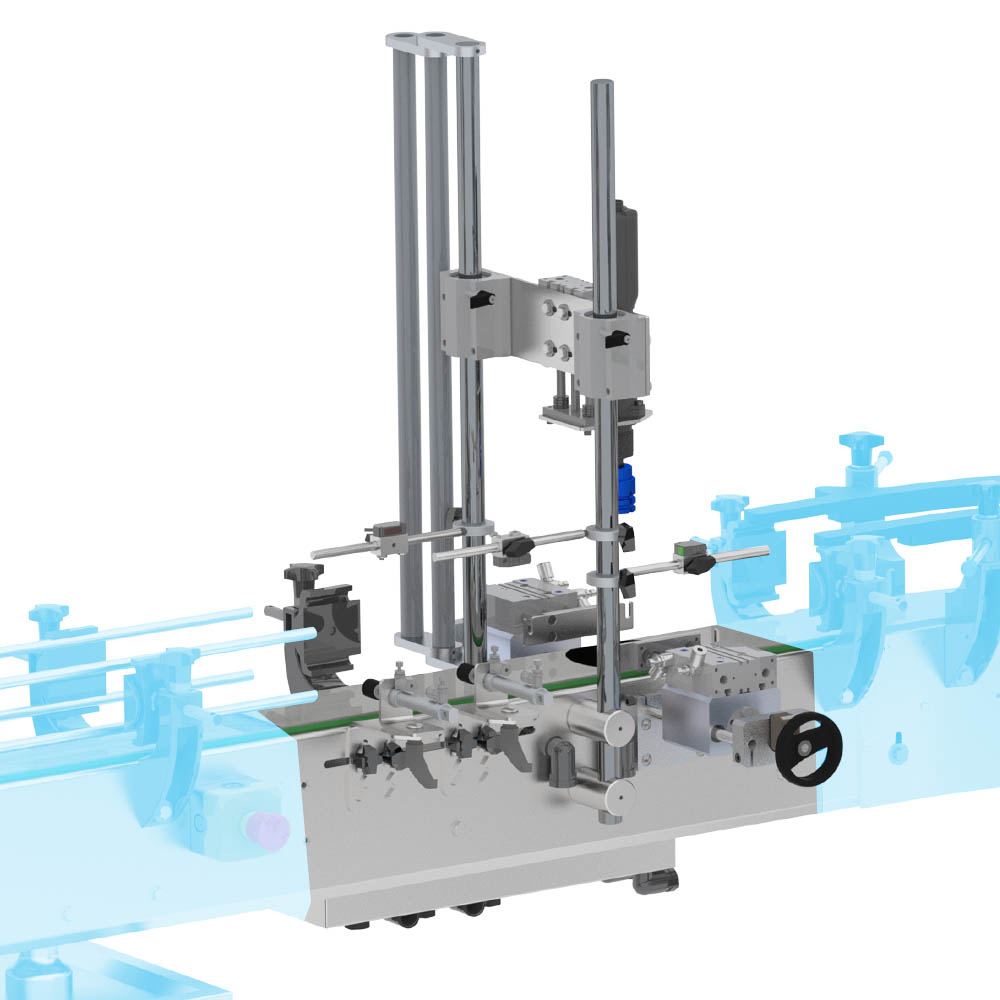

Afterwards, the capping is done by the VS 400. The automatic capping machine offers great versatility and can be used to screw on different types of cylindrical caps, such as vertically grooved caps, pipette caps, pre-threaded screw caps, hinged lids, and many others. The capping process is as follows : the operator manually positions the cap on the container, which is then detected and automatically screwed on by the capping head (the torque is set via the touch screen).

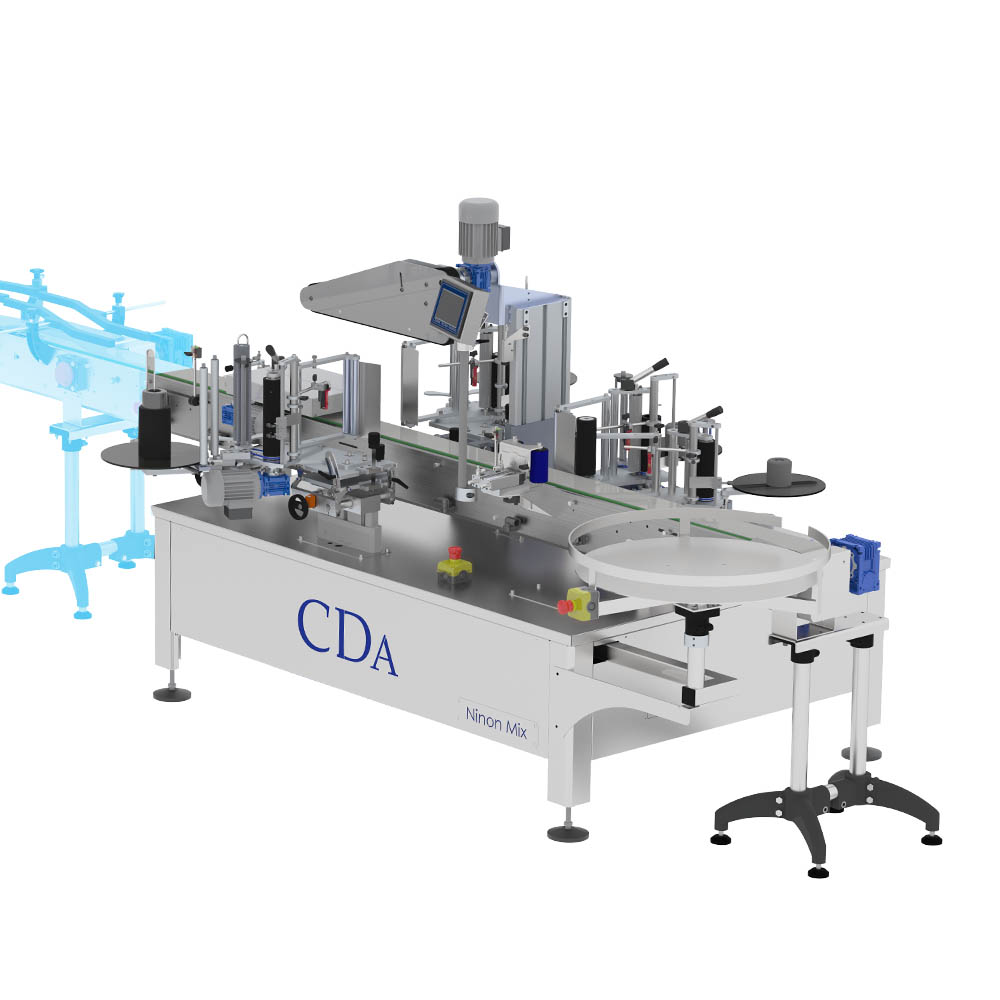

The Ninon Mix machine is used to perform the final labeling. This versatile and very easy to use labeler is capable of labeling square, cylindrical, oval, conical and many other shapes of containers with one or more labels. With an output of up to 20 products per minute, or 1,200 per hour, the Ninon Mix is an efficient solution for labeling large numbers of containers quickly and effectively.

Just like all CDA machines, additional solutions can be added to the complete lines (such as rotary output tables, HSA industrial markers or thermal transfer coders) to provide a tailor-made solution for your project.

If you are interested in our packaging solutions, feel free to contact us so we can discuss your project and provide you with a detailed quote.

Finally, find out more about the applications of CDA’s complete lines through videos on our YouTube channel.

Container shapes

Viscosity

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries