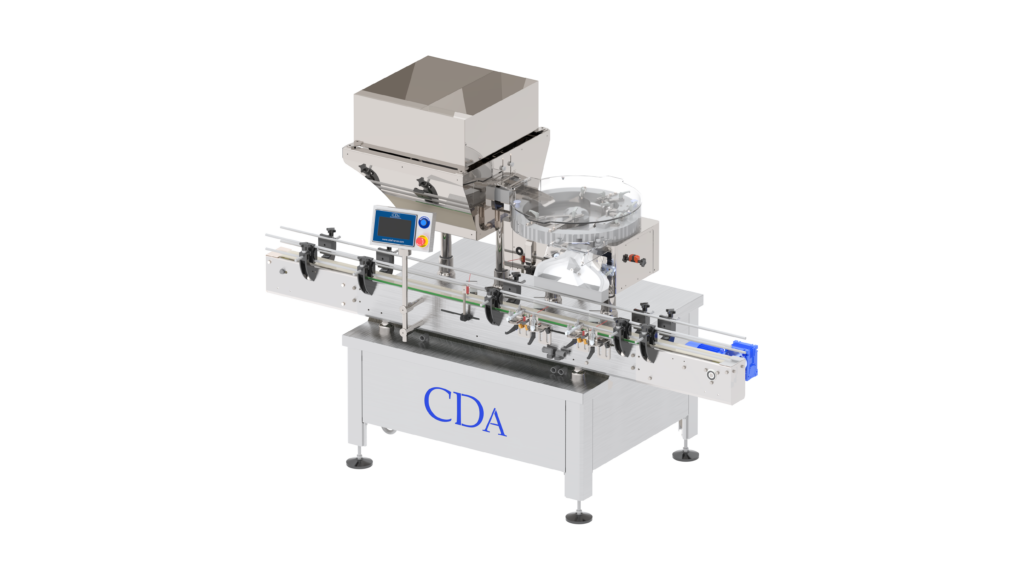

C-Pills Auto Capsule and film-coated tablet counting machine

The C-Pills Auto is an automatic capsule and film-coated tablet counting machine. Designed and manufactured by CDA, this counter meets the needs of the pharmaceutical, food, and animal health industries. It stands out for its durable design, using high-quality materials such as mirror-polished stainless steel, glass, and food-grade plastic (POM C).

- The process begins with a vibrating hopper into which the operator pours the tablets in bulk. Its large capacity allows it to hold up to 60,000 size 0 capsules. In addition, the hopper is electrically height-adjustable, making the operator’s work easier and simplifying cleaning.

- Once transferred from the hopper onto a glass rotary table, the tablets are moved with precision. Optimal spacing between each tablet is created so they can be counted by a laser curtain. After counting, the tablets drop into the counting chamber.

- The containers are conveyed to the counting chamber via a stainless steel conveyor. Automatic indexing is carried out by two sets of double pneumatic cylinders, ensuring precise and secure spacing of the bottles. Detection sensors ensure perfect synchronization between the arrival of the containers and the capsules.

- The height of the counting table is also electrically adjustable. Adjusting its height allows for quick changeovers between different bottle formats, regardless of size, as well as easy assembly and disassembly for regular and efficient cleaning.

- The entire machine has been designed to offer excellent cleanability: the various components are easily accessible and cleanable, meeting pharmaceutical industry requirements. This high level of cleanability facilitates product changeovers.

- The C-Pills Auto guarantees a counting speed of up to 1,000 capsules per minute (size 0). Its 99.99% accuracy ensures reliable, professional counting. Finally, the machine stands out for its ease of use, thanks to intuitive control via the touchscreen.

For complete packaging of your tablets or capsules, from filling, to capping, and finally labeling, CDA also offers a complete line consisting of the C-Pills Auto – VS2000 – Ninon 2500.

FAQ – C-Pills Auto :

1. What is the counting capacity of the C-Pills Auto?

The C-Pills Auto can count up to 60,000 capsules or tablets per hour (size 0), providing high productivity for industrial environments.

2. How does the machine ensure high counting accuracy?

The 99.99% accuracy is achieved through a combination of a counting system with optimal spacing, a high-performance laser curtain, and detection cells that synchronize counting with container arrival.

3. Can the C-Pills Auto adapt to different container formats?

Yes. The height of the counting table and the hopper is electrically adjustable, allowing quick adaptation to different container sizes.

4. How are containers conveyed and positioned?

Containers are transported via a stainless steel conveyor with an automatic indexing system with double cylinders, ensuring precise and repeatable positioning.

5. Is product loading ergonomic for the operator?

Yes. The height-adjustable vibrating hopper makes loading tablets and capsules easier and improves operator comfort.

6. Is the machine easy to clean between production runs?

Yes. The C-Pills Auto is designed for excellent cleanability, with easily accessible surfaces that allow fast cleaning and batch changeovers.

7. What types of products can be counted?

The machine is suitable for counting tablets and capsules of different sizes, thanks to precision guides and adjustable components.

8. Does the machine require complex operator training?

No. The machine is operated via an intuitive touchscreen interface, allowing quick setup and reducing the risk of configuration errors.

9. Can the C-Pills Auto be integrated into a full packaging line?

Yes. The C-Pills Auto is designed for easy integration into a complete packaging line. It can connect seamlessly with upstream and downstream equipment, such as bottle unscramblers, cappers, and labeling machines, ensuring a continuous and automated process.

Viscosity

Capsule

Advantages

- Easy to adjust, use, and clean

- Electric adjustment based on container height

- High-capacity hopper (up to 60,000 capsules per hour)

Characteristics

-

Rate60,000 capsules / hour

-

Accuracy99.99%

-

StructureStainless steel

-

Contact partsPolished stainless steel and food-grade POM C

Industrial sectors concerned

Parapharmacy

Animal products

Food processing

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries