K-Dense Dosing table to fill pasty and thick products | K-Dense

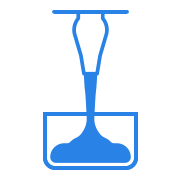

The K-Dense by CDA is an automatic filler developed by our engineering department for a 2-in-1 purpose.

It is a dosing table that automatically feeds containers while filling them.

Thus, this automatic filler has numerous advantages :

- Reduced floor space usage (dosing is performed on the feeding table, eliminating the need for cumbersome conveyors),

- Simplified machine cleaning (the table is cleaned directly, which is more accessible than a conveyor).

Depending on the product to be dosed, engineers equip the K-Dense with a gear pump or a piston. Therefore, the K-Dense dosing table can fill various sizes of glass (or plastic) jars with a wide opening (30g, 50g, 100g, 150g, 200g, 250g, 500g…).

Thick, paste-like, and semi-dense products (such as jam, honey, maple syrup, sauces, mustard, spreads, pâté, terrine) are perfectly dosed with the K-Dense.

The automatic filler K-Dense can fill up to 1.5 tons per day.

It integrates seamlessly into a complete packaging line, which can include a capping solution (such as the VS500 capper) and an automatic labeler (Ninon 1500/2500).

For more information about this filling machine, feel free to contact us.

Lastly, discover all CDA packaging machines in video format on our YouTube channel.

Viscosity

Thick

Heavy

Advantages

- 2 in 1 table; feeding & dosing

- Small footprint and easy to clean

- For pasty/thick products; honey, pâté, sauces...

- Integration into a complete packaging line

Characteristics

-

Filling rateup to 1.5 tons per day

Industrial sectors concerned

Food processing

You may also like

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries