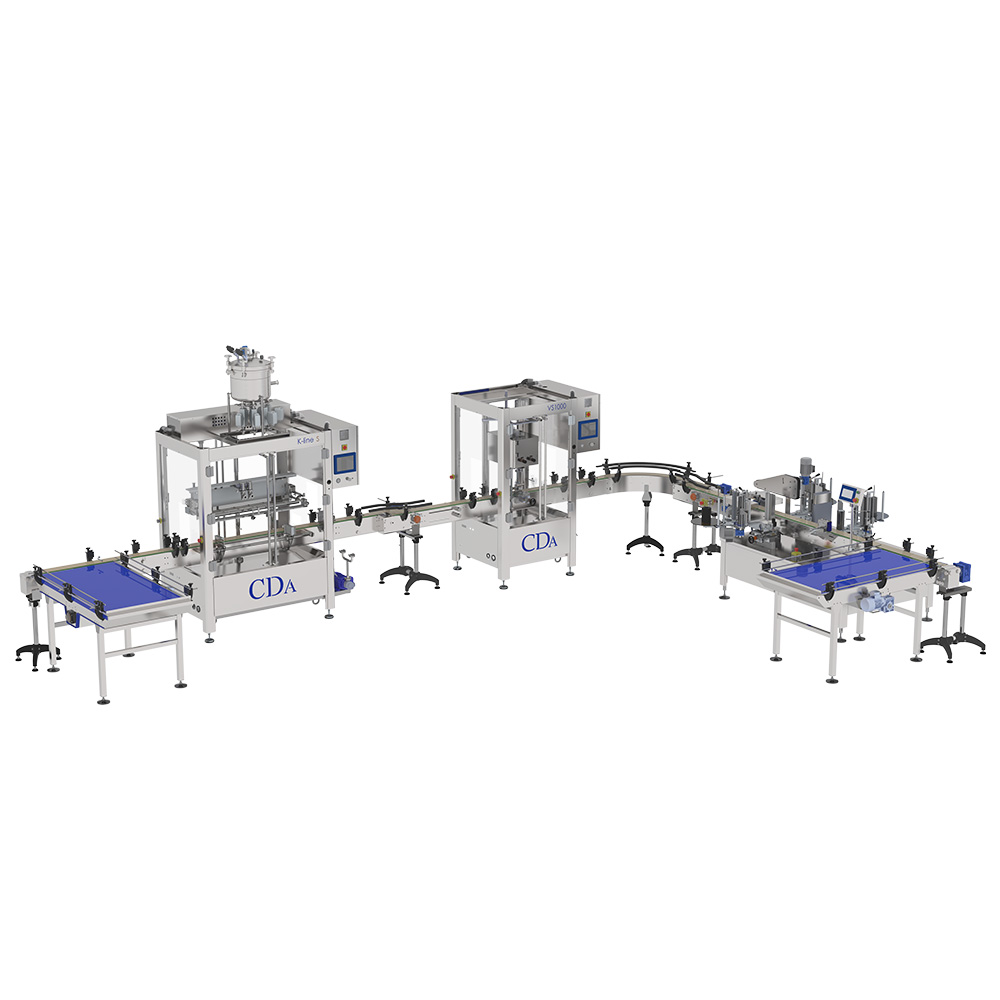

Complete line : K Line S – VS1000 – Ninon Mix Automatic complete line for all industries | K Line S + VS 1000 + Ninon Mix

CDA proposes complete lines combining the three key stages of packaging. Our lines can be adapted to the specific needs of the customer (additional options can be added). Nevertheless, their objective remains the same : filling, capping, and labeling.

In this line’s configuration, filling is carried out by the K-Line S. This automatic filler is versatile, capable of filling up to 3000 liters per hour (50 liters per minute) while maintaining a precision of +/- 0.5%. The speed varies depending on the dosed volume and the specificity of the product to be filled. Its dosing system is adapted to your products (volumetric, flow meter, centrifugal and more types of dosing.).

For capping, we propose the VS1000. This linear capping machine is fully enclosed (for increased safety) and is equipped with a motorized conveyor. The conveyor can have curves to adapt to the specificities of our clients’ workshops. The VS 1000 can handle a wide variety of caps such as gun caps, spray caps, pipette caps, and more, thanks to its capping system driven by electric screwdrivers.

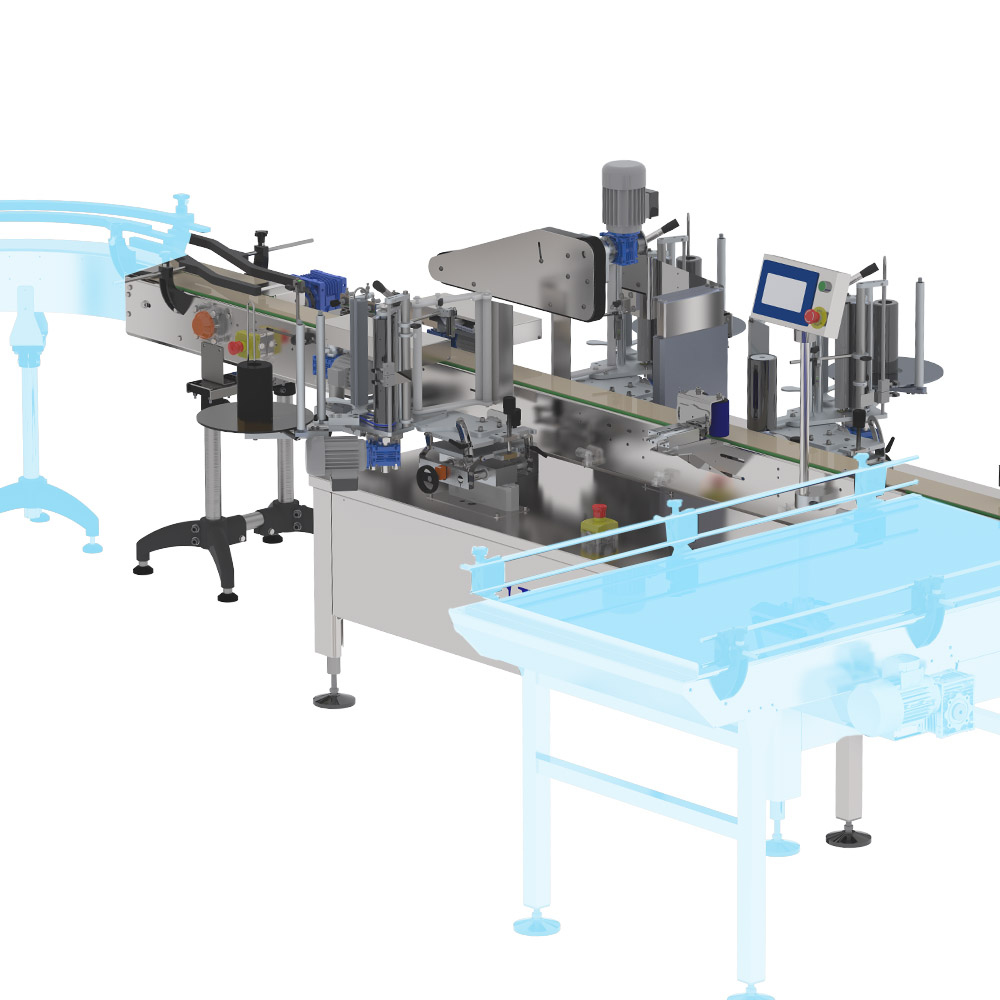

Finally, the Ninon Mix is used for labeling products that have been filled and capped beforehand. If necessary, this machine can be enclosed (for increased safety). The Ninon Mix is appreciated for its versatility : it applies adhesive labels to a variety of shapes, including cylindrical, conical, oval, and rectangular. It can also achieve a production speed of up to 35 products per minute.

We propose complementary solutions that can be added to this all-in-one packaging line, such as rotary output tables, HSA industrial markers or thermal transfer coders. In this way, we can provide a customized solution that perfectly suits your projects.

Container shapes

Viscosity

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries