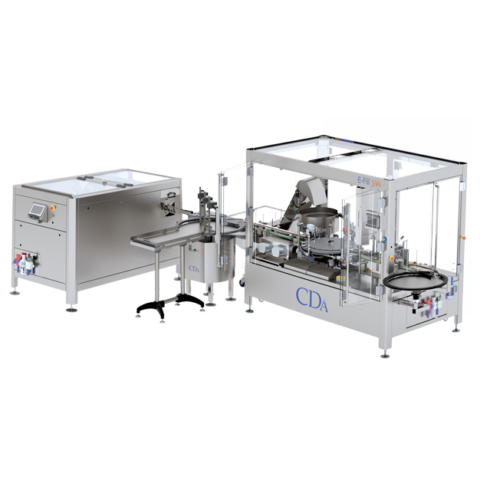

The latest innovation created by CDA, the E-Fill SW is a delight for producers with a wide range of bottles and caps. We had the pleasure of recording our E-Fill SW in action directly with one of our e-liquid manufacturer customers.

A worthy successor of the E-Fill S

The E-Fill SW comes to improve an already existing machine and acclaimed by our customers; the E-Fill S. Created to offer complete automation of the packaging chain, the E-Fill S allows 100% automatic bottles filling, capping and labeling. Its feeding table, dosing, Pick & Place automatic cap removal system, labeling and accumulation table make lead to independent operation of any operator intervention. Ideal for 5ml to 250ml vials automatic packaging, the E-Fill S is appreciated for its 50 products / minute production rate offering an excellent yield for massive production.

Our customers need versatility!

On the field by your side, our teams have seen the emergence of a real need for versatility among many of our customers. If some produce a single product format, several of our customers must package a main product with a variety of complementary products packaged in different bottles and caps. Therefore ,our team wanted to allow customers meeting these constraints to condition their main production in a 100% automated manner as the E-Fill S allows, while offering them the possibility of packaging on the same machine a large variety of other bottles and caps in semi-automatic mode.

A full automatic mode & a semi-automatic « switch » mode

To do this we have created the E-Fill SW, capable of operating both in automatic mode and in a second mode, called switch mode. This new mode consists in deactivating the Pick & Place system working with certain types of caps and thus allowing an operator to hand place other types of caps. These will then be tighten automatically using a second capping system installed on the machine. The creation of our E-Fill SW required several adjustments in its design to make it as functional as possible. To ensure maximum safety and comfort for the operator, deactivation of the Pick & Place system allows the rotating star wheel (in which the products are filled) to rotate in the opposite direction. The operator can then safely hand place the caps which will then be tighten automatically. Our door system has also been updated to open in an accordion style and thus save space. As for the machine screen, it is now swivel, making adjustments more accessible and easier depending on the operator’s position.

The E-Fill SW was therefore created to allow the greatest versatility to our customers. Improved version of the E-Fill S, it brings a lot of innovations for efficient and precise packaging of your various bottles. It will be the perfect ally of e-liquid, essential oils, food flavors or dyes manufacturers with a wide range of bottles and caps in their production as well as those who plan to diversify their range in medium or long term. Similar to all the packaging tools offered by CDA, the E-Fill SW demonstrates precision, reliability and adaptability. To find out more about this complete automated line, please do not hesitate to contact our team!

+1 804-918-3707