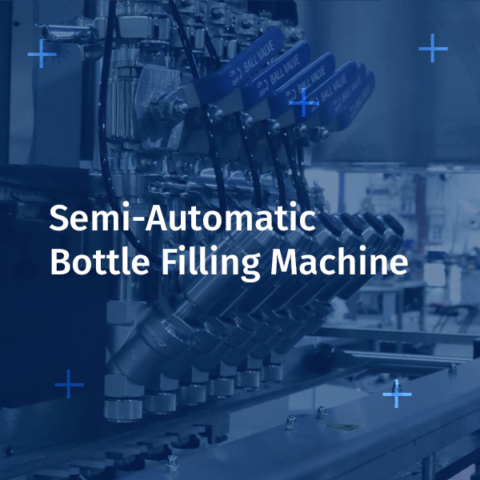

In many industries, choosing the right packaging equipment is a strategic decision. Between manual fillers which are limited in speed and fully automatic systems, which require a higher investment, the semi-automatic bottle filling machine offers a balanced solution.

Versatile, precise, and cost-effective, it meets the needs of businesses looking for productivity and flexibility without compromising on quality.

1. What is a Semi-automatic bottle Filling Machine?

A semi-automatic bottle filling machine is designed to accurately dose a liquid or semi-liquid product into a container (bottle, jar, pot, or jug).

Unlike a manual system, it automates the dosing and filling process while leaving some tasks to the operator, such as:

- Placing containers,

- Starting the filling cycle,

- Removing filled products.

Available technologies:

- Peristaltic pump : Ideal for sensitive products or quick product changes (essential oils, e-liquids, flavorings).

- Piston filling : Perfect for viscous products like creams, gels, sauces, or pastes.

- Gravity or flowmeter filling : Suitable for low-viscosity liquids such as oils or juices.

2. Production Benefits

Flexibility

Capable of handling multiple formats and volumes, a single machine can fill anything from a 10 ml vial to a 1 L bottle.

Precision

Calibrated dosing systems guarantee consistent volumes, reducing variations and material waste.

Time Savings

Compared to manual filling, production speed is significantly higher, boosting output.

Controlled Investment

Semi-automatic solutions are more affordable than fully automated systems while still offering performance suited for growing production.

Product Versatility

Handles a wide range of textures: liquids, semi-liquids, viscous products, and foaming products.

3. Multi-Industry Applications

- Food & Beverage: oils, syrups, sauces, juices, vinegars.

- Cosmetics & Personal Care: creams, gels, lotions, shampoos.

- Chemical Products: detergents, solvents, cleaning agents.

- E-liquids & Flavorings: small formats with high-precision dosing.

4. Spotlight on Our Machines

At CDA, we offer several semi-automatic machines tailored to the needs of various industries:

- K-Net : Compact and easy to operate, ideal for small to medium runs.

- K-Dense (if applicable): Specifically designed for thick and pasty products.

- Available options : Drip-free system, quick volume adjustments, compatibility with foaming products.

5. Integration into a Packaging Line

A semi-automatic filler can be used:

- As a standalone unit, in a small workshop or for short-run productions.

- As part of a partial integration, with a labeler and capper to form a semi-automated line.

- As a step toward full automation, with upgrade options such as the K-Net Auto or K-Line.

6. Tips for Choosing the Right Machine

- Identify the viscosity and nature of the products to be filled.

- Define your target output and production volume.

- Choose the dosing technology best suited to your products.

- Plan for future production growth and select an upgrade-ready model.

Conclusion

The semi-automatic bottle filling machine is the ideal tool for companies seeking accuracy, speed, and versatility while keeping investment under control.

With robust, upgradeable, and easy-to-use models, CDA USA supports producers of all sizes in optimizing their packaging lines.