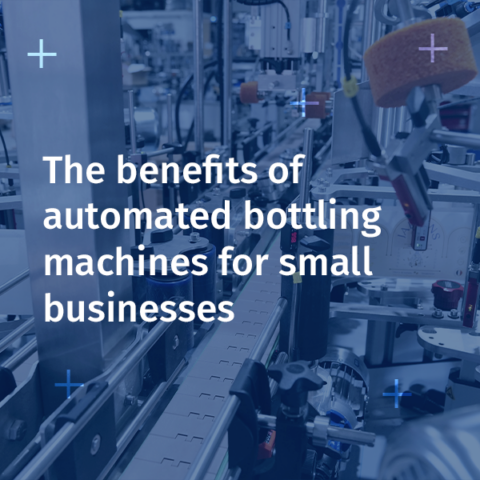

Automatic machines are no longer just for large companies. They are becoming indispensable for small businesses looking to improve efficiency, reduce costs, and see a quick return on investment. Here’s why investing in automation is a smart decision for your business.

1. Increased productivity

Automatic machines streamline production lines. They can fill, cap, and label products much faster than manual methods. For example, an automated bottling machine can process between 600 to 1,200 bottles per hour, while a manual team can only handle a few hundred. This time-saving directly translates into higher production output, allowing you to meet demand more quickly. The less time spent on each product means more finished products in less time, leading to vastly improved efficiency.

2. Fewer errors, less waste

Manual dosing is often prone to errors, leading to volume discrepancies, product loss, and inconsistent quality. With automatic machines, you get optimal dosing precision. Each bottle receives the exact amount of product, significantly reducing waste. Studies show that manual methods can result in 5-10% product loss, while automatic machines reduce this to less than 1%. Less waste means more savings and better resource management.

3. Flexibility and scalability

Small businesses evolve, and their production needs can change rapidly. Automatic machines are modular and scalable, allowing you to meet spikes in demand without needing to invest in new equipment each time. You can start with a machine suited for moderate volumes and easily increase capacity as your production grows, with no major interruptions. This flexibility helps you meet growing demand quickly while avoiding unnecessary re-equipment costs.

4. Greater reliability

Machine downtime can be costly in terms of lost time and production. Modern automatic machines are designed to be more reliable, with real-time diagnostic systems and more robust components. According to experts from the PMMI (Packaging Machinery Manufacturers Institute), modern machines reduce downtime by up to 30% compared to older models. Fewer breakdowns, fewer unexpected costs, and more consistency in production all help maximize profitability.

5. Return on Investment

While the initial investment in an automatic machine may seem significant, the long-term benefits far outweigh the cost. Lower labor costs, less waste, and more finished products per hour all contribute to a quick return on investment. Generally, an automated machine pays for itself in 1-2 years, depending on production volumes. Additionally, a McKinsey study found that businesses investing in automation increase their profitability by 20-30% in the first three years. For small businesses, this means that automation can not only improve profit margins but also support sustainable long-term growth.

Automatic machines are an efficient solution to boost productivity, reduce costs, and offer a fast return on investment. They help small businesses grow while optimizing their production processes.