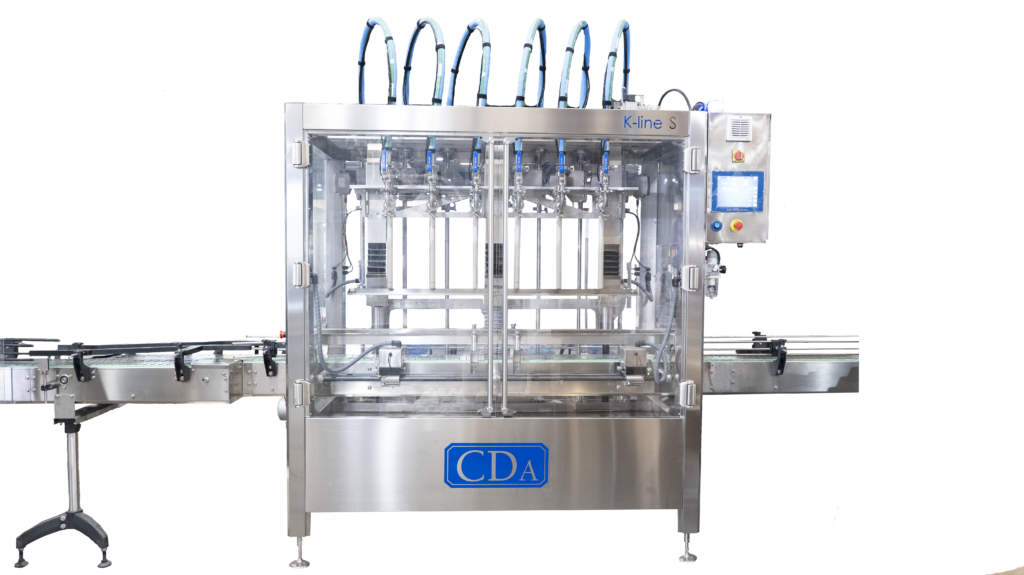

K-Line S Automatic filling machine with pressurized tank and clean in place system | K-Line S

The K-Line S is an automatic filling machine capable of handling various types of liquids. Indeed, it can handle fluids, foamy, thick, or pasty viscosities. Depending on the viscosity of the products to be filled, it will be equipped with the most suitable dosing system (flowmeter, pump, or piston, as well as plunging nozzles if necessary). Our fillers work with all shapes containers: round, tapered, flat, oval.

The K-Line S can thus be suitable for various sectors of activity, such as :

- Agri-food (for example, for dosing fruit juice, soup, or sauce),

- Chemistry (for filling detergent drums, household products, etc.),

- Cosmetics (for filling various shampoo bottles, soap bottles, and others).

This filling machine is available in 3 sizes (depending on the number of dosing nozzles : 2, 4, 6, or 8). It is equipped with a stainless steel frame, a conveyor (with various widths and lengths possible), a product centering system, a droplet collection device, a liquid recovery tray, and a touch screen. It can have a variety of options, such as a pressurized tank (praised for its self-cleaning system), an embedded capping system, etc.

Accurate, the K-Line S filling machine ensures the dosing of products at a rate of up to 2500 liters per hour. This rate varies depending on the dosed volume and the type of product.

True to CDA’s DNA, the K-Line S automatic linear filling machine is easy to use, adjust, and clean. It can be used independently but can also be integrated into a line with an automatic capping machine (such as the VS2000) and a labeler (from the Solo or Ninon range).

For more information on the K-Line S, do not hesitate to contact us.

You can also find out more about all of CDA’s packaging machines, on our YouTube channel.

Viscosity

Fluid

Heavy

Thick

Advantages

- 2 to 8 filling nozzles (plungers optional)

- From 2oz up to 5 Gal

- Simplified management by touch screen

- Automatic product centering

Characteristics

-

Filling speedUp to 660 Gallons (2,500 L / hour)

-

TankPressurized

Industrial sectors concerned

Chemicals

Cosmetics

Food processing

Our K-Line S references

You may also like

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries