K-One Filling machine for liquid products using a peristaltic pump | K-One

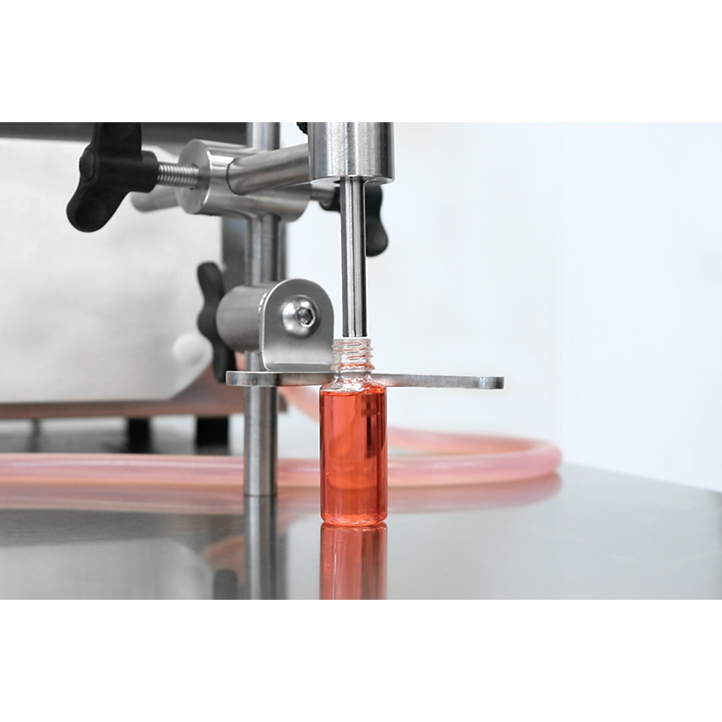

Developed by CDA engineers using the best materials on the market, the peristaltic filling pump K-One stands out for its precision and versatility.

This peristaltic filling system is equipped on monoblocs (such as the E-Fill or E-Fill SW) but can also be used manually and independently.

Indeed, the K-One allows for :

- an automatic use when installed on a monobloc (3-in-1 packaging machine for filling, capping, and labeling cylindrical containers),

- an independent use in “manual” mode for dosing small productions.

Moreover, the peristaltic pump dosing technology offers multiple advantages :

- The product to be dosed does not come into direct contact with the moving parts of the pump (only with the tubes),

- Tube changes are extremely fast,

- Cleaning time is minimized (just change the tubes),

- Cross-contamination risks are very low,

- The technology adapts to corrosive products (there are various plastic options).

Therefore, the K-One is the ideal system for packaging products in various sectors, such as :

- e-liquids,

- natural flavors,

- essential oils, and so on.

Generally, this dosing system is favored by companies that produce and package many small-sized products (up to 1 liter). The time savings are significant when changing the product to be packaged.

The K-One can be complemented with a semi-automatic capping and labeling system to carry out the 3 key packaging steps at a lower cost. For instance, the VS 100 and the Ninette Auto are often purchased with this semi-automatic filler.

Discover all of CDA’s filler videos on the YouTube playlist !

Viscosity

Fluid

Advantages

- Automatic or semi-automatic mode

- No fluid contact with the pump for a fast liquid changeover and easier cleaning

- Highly flexible, reliable and easy to use

- Stand-alone use and/or integrable in automatic filling lines

Characteristics

-

Production rateUp to 1500 products/hour for 10mL

-

FunctionsVolume, Speed control, suck-back, acceleration, deceleration…

-

Special featuresAutomatic settings calculation, Prime, Memory 96 lines

Industrial sectors concerned

Food processing

Cosmetics

E-liquids

Chemicals

Our references K-One

You may also like

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries