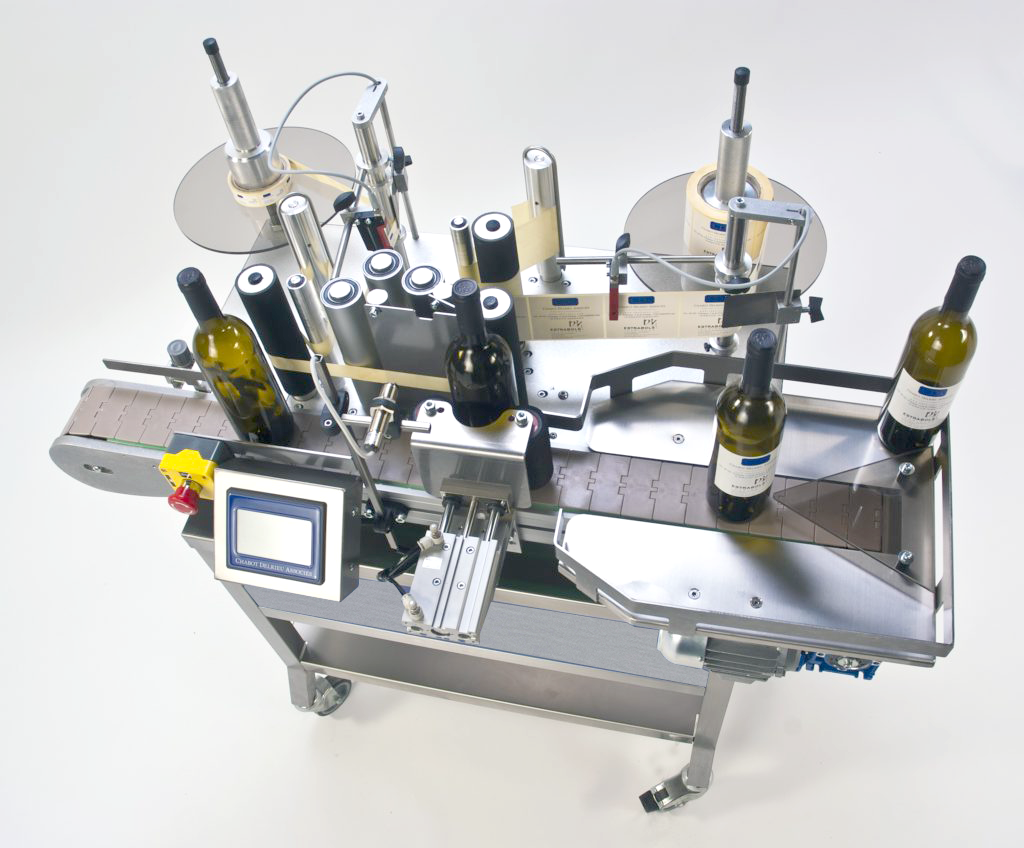

Semi-automatic

Small labelers for big projects!

Labelers belonging to the semi-automatic range are halfway between a manual packaging and an automatic machine. They also offer an attractive solution for large companies launching a new product (without a significant initial investment).

What are the advantages of the Ninette range of labelers? There are far too many!

First of all, the Ninette are affordable labeling machines that allow accurate and efficient labeling. The labeling technology used on Ninette range is the 3-point technique : the product is rotated on itself with the help of a smoothing roller and a pressure plate cylinder. When the product is rotated, the machine applies one or more labels. This technology provides the most accurate labeling results and a perfect application of self-adhesive labels.

Plus, the materials used in the construction of the Ninette, such as aluminum or stainless steel, allow these machines to last a long time. The Ninette can label up to 1000 bottles/hour and are compact (30 kg with dimensions 65x61x110 cm). This saves a lot of space and time for small companies that can focus on their core business. Ninette machines are used in almost all sectors of activity such as the food industry, the wine industry, the chemical industry, the cosmetics industry, etc.

The machines in the semi-automatic range are :

- Ninette 1: this labeling machine supports only one label roll, so it applies only one label. It is adapted to cylindrical products.

- Ninette 2: this labeling machine supports 2 rolls of labels, so it can apply 2 labels on cylindrical products.

- Ninette Flat: is designed to label products with flat surfaces.

- Ninette Auto: is the intermediate machine between a semi-automatic and an automatic labeler. This labeler is composed of a motorized conveyor that allows the products to be conveyed to the labeling system.

- Ninette Auto Mini: is identical to the Ninette Auto but has been designed to label smaller cylindrical products (between 20 and 45mm).

Advantages

- Up to 2 adhesive labels

- Easy to operate

- high quality and affordable machine

Characteristics

-

Labeling rateUp to 600 bottles/hour

-

Machine controlVia intuitive touchscreen

Industrial sectors concerned

Chemicals

Beverages

Coatings

Cosmetics

E-liquids

Food processing

Brewery

You may also like

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.