Complete semi-automatic line: K-One + VS 100 + Ninette auto mini Complete semi-automatic line for packaging small products | K-One + VS 100 + Ninette auto mini

This semi-automatic complete line for small products consists of three machines that bring together the three key stages for packaging your products. In short, a filler, a screwer / capper and a labeler.

It is the ideal configuration for small productions with machines particularly adapted to cylindrical products. The output of the complete line for small products can reach up to 25 packaged products per minute or 900 products/hour. Composed of a K-One for filling, a VS 100 for capping and a Ninette Auto Mini, this line is suitable for products from 5ml to 250 ml.

- The K-One is the first step in the filling process. It is a peristaltic pump which by its design allows the product to be in contact only with the tube. This ensures hygienic dosing. Its filling rate is 15 products/minute for liquid products with a precision of +/- 1%. This pump is very well adapted to the food, cosmetic, pharmaceutical or e-liquid sectors.

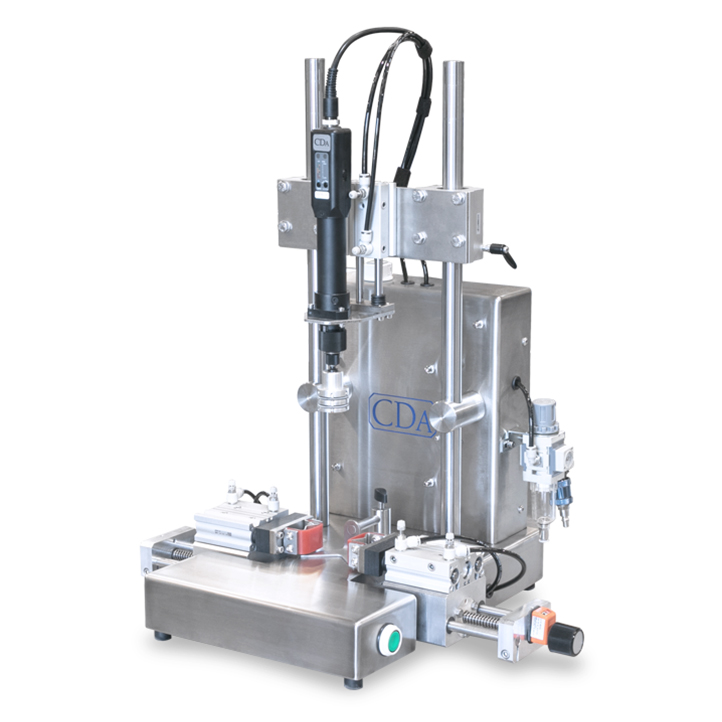

- The second step of the packaging process is carried out by the semi-automatic capping machine VS100 with two-hand control. It has a capping head designed according to the type of caps to be screwed and allows an adjustment of the capping torque on the head. Easy to use, it is suitable for a wide range of products and containers in many sectors of activity.

- Finally, the Ninette Auto Mini for cylindrical products can be used for labeling. It can label bottles with a minimum diameter of 20 mm and apply up to 2 labels (label and back label). The machine is operated via an intuitive touch screen and the speed of the labeler can reach up to 15 products/minute.

Of course, it is possible to add to this complete semi-automatic line, complementary solutions such as HSA industrial markers to affix a DLC, a bar code or a DLUO.

If you are interested in our packaging solutions, feel free to contact us so we can discuss your project and provide you with a detailed quote.

And finally, explore the applications of CDA’s complete lines in videos on our YouTube channel.

Container shapes

Viscosity

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries