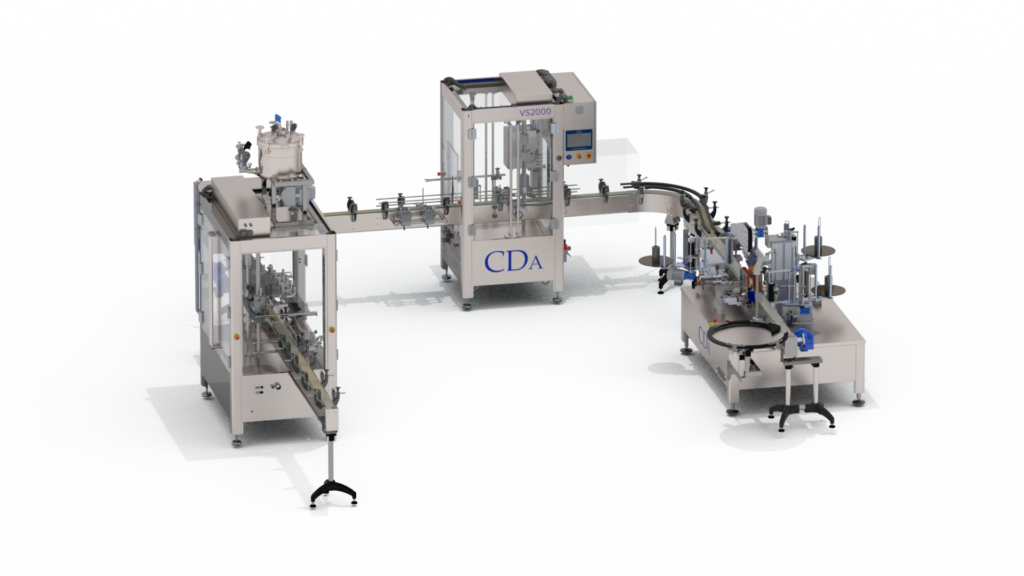

Ligne complète : K Line S – VS2000 – Ninon Mix Complete 3-1 automatic line for all products

CDA provides comprehensive solutions that incorporate the three fundamental stages for packaging your goods: filling, capping, and labeling.

Within our product range, the enclosed linear filler K-Line S stands out due to its user-friendly interface and ease of adjustment. This highly versatile machine is also commended for its ease of cleaning. Depending on your product specifications, we can tailor the dosing system to measure volume using one or more pistons or to measure flow, with or without a pressurized buffer tank. With the K-Line S, you can fill up to 3,000 liters per hour while maintaining dosing accuracy within +/- 0.5%. We also offer Gallon Filling Machines designed to handle larger volumes, ensuring efficient and precise filling for gallon-sized containers.

When connected via a linear conveyor (or a curved/U-shaped conveyor, as per your workshop’s requirements), the VS2000 capping machine automates the feeding and capping of a wide variety of closures. This capping machine is fully enclosed to ensure maximum safety. Its capping system, driven by electric screwdrivers, is perfectly suited for spray caps, flat caps, ribbed caps, and many other types of closures.

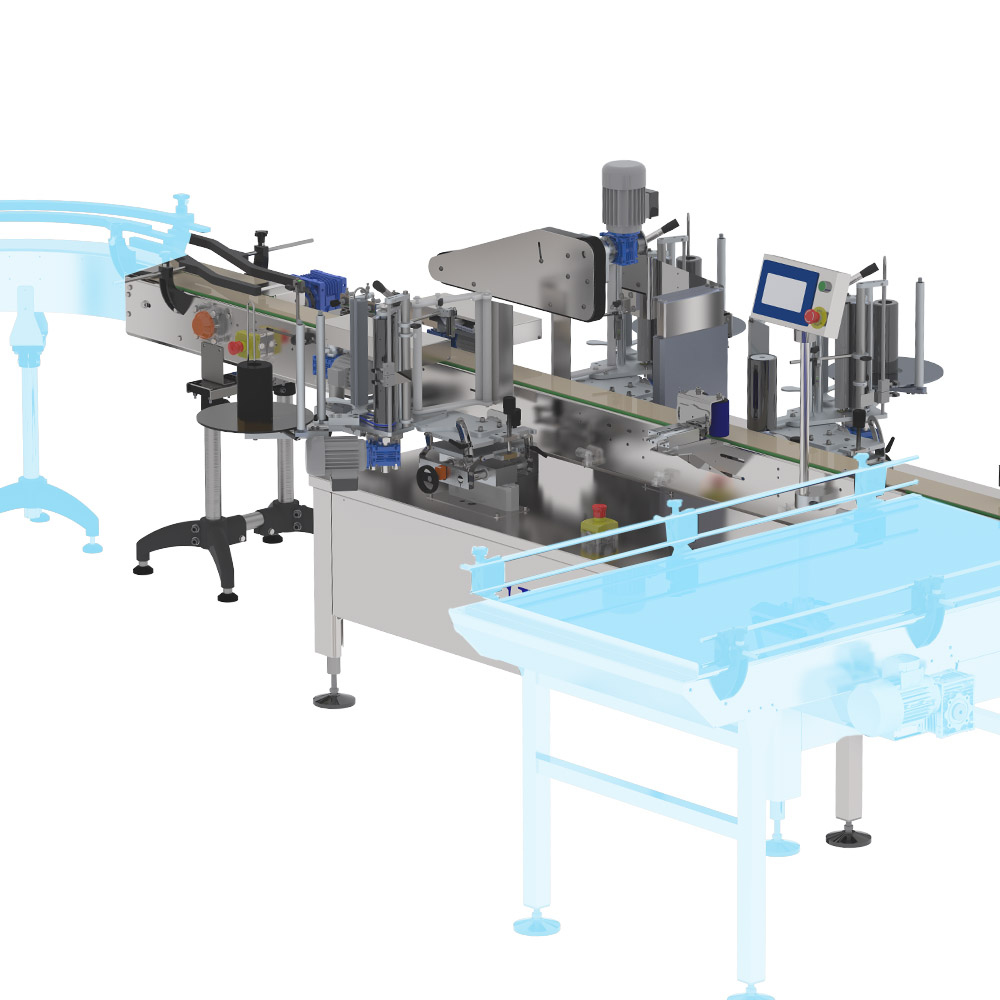

The Ninon Mix labeler takes care of the final step in your packaging line. This labeling machine can be configured for cartoning upon request. The Ninon Mix is distinguished by its versatility, capable of applying up to 5 self-adhesive labels. Furthermore, it adapts to a diverse range of product shapes, including cylindrical, conical, oval, or rectangular. This automated labeling machine can handle up to 35 products per minute. Additionally, our Gallon Labeling Machines are designed to efficiently label gallon-sized containers with precision.

To tailor our solutions to your specific needs, we offer the integration of complementary solutions into this comprehensive 3-in-1 packaging line. These supplementary solutions may encompass infeed/outfeed tables, marking/coding systems, conveyors, and any other elements required for the packaging of your products.

Feel free to reach out to our team of packaging experts to discuss your project!

Container shapes

Viscosity

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries