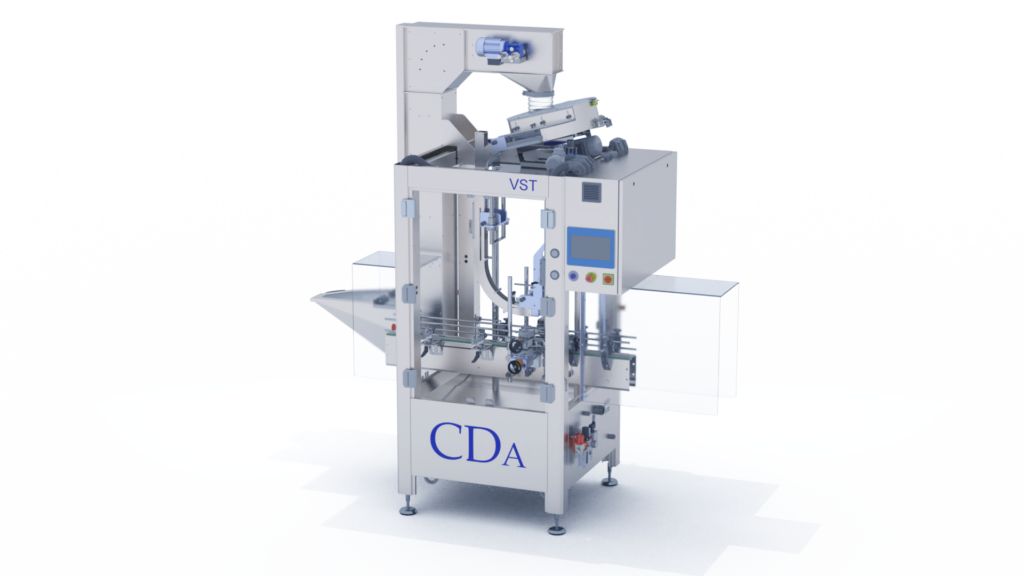

Automatic cork dispensing VST Cork dispensing and pressing system

The VST is a system designed to automatically distribute and press T-top corks onto bottles. This automatic machine is linear, made of stainless steel, and encased. It is designed and manufactured by CDA. The VST can achieve a speed of up to 1800 corks/hour (depending on the type of cap, any downstream machines, and so on.).

In terms of its operation, here are the different stages of the system :

- Corks are introduced in bulk into a hopper (associated with an elevator),

- The elevator retrieves the corks to automatically transport them (gradually) into an orientation bowl,

- The orientation bowl aligns the corks in the correct direction before distributing them one by one on a ramp,

- From this ramp, the corks are distributed right at the neck level of the bottle.

It’s worth noting that the elevator is a standard element, providing better autonomy and simplifying the operator’s work by eliminating the need to manually transport corks to the orientation bowl.

The VST perfectly meets the needs of companies in the distillery or agri-food industries, which frequently use T-top corks to seal their bottles. This machine is appreciated for its versatility and simplicity of operation and adjustment (such as the insertion/seating force).

The VST can be used independently or integrated after a CDA linear filler (such as a K-Net Auto) or before a labeler. The VST has its very own spot in a complete packaging line.

For more information on the VST machine, feel free to contact our team through the form on our website. You can also reach us by phone (804.918.3707) or email (contact@cda-usa.com).

Finally, watch all of the CDA screw capping machines in action on our YouTube channel.

Formes des bouchons / capsules

Advantages

- Automatic dispensing and pressing

- Suitable for T-caps

- Simple to operate

Characteristics

-

Automatic cork dispensingCustom made and adapted to the cork

Industrial sectors concerned

Food processing

Brewery

Our references VST

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries