Since 1991, we have been designing and manufacturing filling, capping, and labeling equipment for a variety of industries, including animal health, natural products, over-the-counter pharmaceuticals, and more.

Our machines are engineered to deliver precision, efficiency, and adaptability, meeting the diverse needs of businesses of all sizes. To support your decision-making, we also provide a comparison guide to help you find the most suitable machine for your production needs.

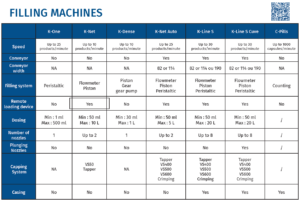

1. Filling Machines: For all formats and product types

Whether semi-automatic or fully automated, our fillers guarantee accurate dosing, quick cleaning, and easy adjustments.

Semi-automatic Fillers:

- K-One: Designed for small volume dosing, equipped with a peristaltic pump that enables quick product changeovers.

- K-Net: Ideal for semi-automatic liquid filling, with the option of a remote filler for larger containers.

- C-Pills: Built for precise counting of capsules and tablets, with a speed of up to 1,000 units per minute.

Automatic Fillers:

- K-Dense: Gear pump-equipped, ideal for thick products like honey, with an integrated feeding table.

- K-Net Auto: Compact and flexible, handles automated liquid filling at a rate of up to 1,200 products per hour.

- K-Line S: A high-performance solution designed for medium to high production volumes, reaching up to 2,500 L/hour.

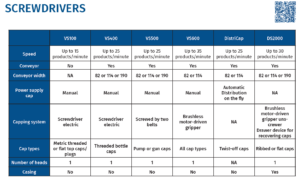

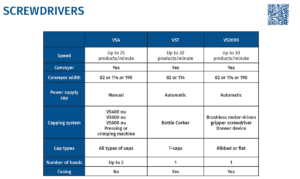

2. Capping Machines: Versatile solutions for all cap types

Semi-automatic Cappers:

- VS 50: Ideal for small batches, compatible with smooth or ribbed caps.

- VS 100: Equipped with a custom capping head, with built-in torque adjustment for precise tightening.

Automatic Capping Modules (to be integrated into a filler or labeller):

- VS 400: Designed for cylindrical caps, ribbed caps, or pipettes; handles up to 25 products per minute.

- VS 500: Ideal for pump or spray caps, with manual height adjustment.

- VS 600: Features a motorized gripping head or venturi system; known for its ease of use and versatility.

Automatic Capping Machines:

- VSA: A modular capping machine that can be equipped with two capping systems (VS 400, 500, 600, or a push-on system).

- VS 2000: Enclosed version with automatic cap feeding and application, suitable for caps from 20 mm to 75 mm in diameter.

- DistriCap: Automatically orients and distributes twist-off caps and other cap types.

- VST: Designed specifically for T-caps, ensuring precise and reliable placement.

- DS 2000: Automatic decapping machine for industrial applications requiring product reopening.

3. Labeling Machines: Precision, flexibility, and high performance

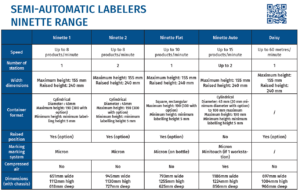

Ninette Semi-automatic Range:

- Ninette 1: For labeling cylindrical products at speeds up to 10 products/minute.

- Ninette 2: Applies two labels in a semi-automatic process.

- Ninette Auto: Up to 13 products/minute with one or two labels, offering precise application.

- Ninette Flat: Ideal for square, flat, or rectangular bottles and containers.

- Daisy: Separates labels from their liner, facilitating liner recycling.

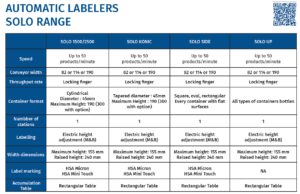

Solo Automatic Range:

- Solo 1500/2500: Applies a single label to cylindrical products.

- Solo Konic: Designed for conical containers, with speeds up to 50 products/minute.

- Solo Side: Applies side labels on flat or rectangular products.

- Solo Up: Top label application, ideal for trays and cartons.

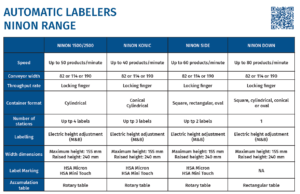

Ninon Automatic Range:

- Ninon 1500/2500: Applies multiple labels on cylindrical products.

- Ninon Side: For side labeling of flat products, up to 60 products/minute.

- Ninon Up & Down: Simultaneous top and bottom labeling for various shapes and formats.

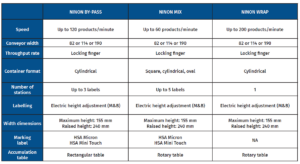

- Ninon Wrap: Full wrap-around labeling for cylindrical items, up to 200 products/minute.

- Ninon By-Pass: Labels up to 120 products/minute with maximum format flexibility.

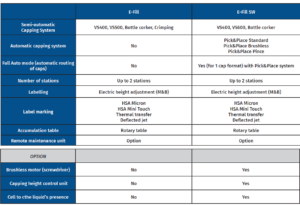

4. Monoblocs: A compact 3-in-1 solution

CDA monoblocs combine filling, capping, and labeling functions into a single, compact machine—ideal for saving space while optimizing output.

- E-Fill: 3-in-1 system for small formats, up to 25 products/minute.

- E-Fill SW: Includes automatic cap feeding, with a speed of up to 50 products/minute.

Conclusion

We offer a complete range of packaging machines tailored to your production speed, product type, and workspace requirements. Thanks to our dedicated R&D department, we can also develop custom solutions for your most specific needs.