Automatic capping machine VS 2000 Encased automatic capping machine for caps placement and closing | VS 2000

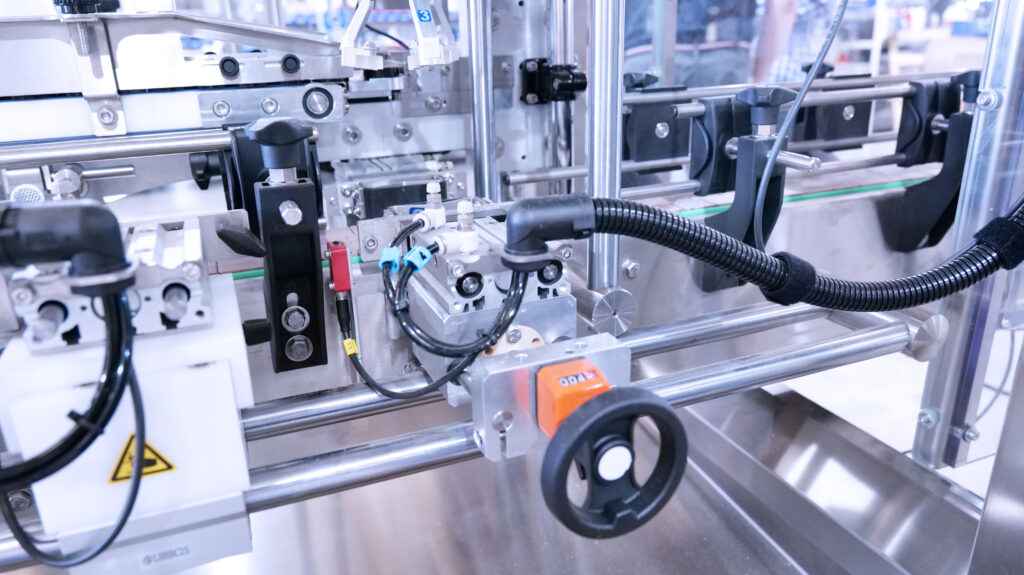

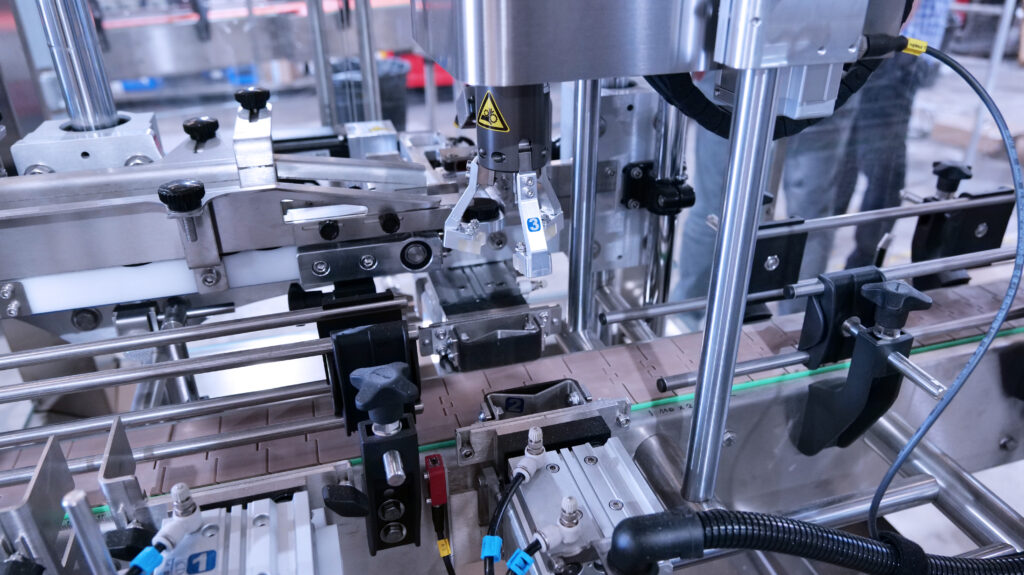

The automatic capping machine VS 2000 is a machine designed and manufactured by CDA. It allows the automatic feeding of caps onto the containers and subsequently the capping. The machine is equipped with a fully stainless steel encased chassis. The VS 2000 is available in three sizes of stainless steel conveyors (82.5 mm, 114 mm, and 190 mm).

This capping machine can handle a wide variety of caps (with a diameter ranging from Ø20 to 75 mm). Depending on the customer’s requirements, the VS 2000 is equipped with a suitable gripper or spur gear head. It can handle smooth caps, hinged caps, childproof caps, ribbed caps, caps with built-in lids, and many more.

Its operation is straightforward : a vibratory bowl transports the caps to a multi-format belt conveyor. A sensor detects the presence of the caps, and a mechanism conveys them to the capping head. As for the capping and torque adjustment, they are performed by a brushless motor.

The VS 2000 operates autonomously and is controlled by an intuitive touchscreen. However, it can also be integrated with other CDA machines (to form a complete packaging line) such as :

- a filler (for example, the K-Net Auto or the K-Line S),

- a labeler (Solo range, Ninon range).

Thanks to its versatility, this automatic capping machine can be adapted to various industries, including :

Feel free to contact our sales team for more information about the VS 2000 !

Lastly, don’t forget to visit our YouTube channel, where you can discover all our capping machines in action, as well as our fillers, labelers, and monoblocs !

Formes des bouchons / capsules

Advantages

- Automatic cap feeding directly on the container

- Enclosed automatic capping machine

- Machine suitable for capping a wide range of caps

Industrial sectors concerned

Beverages

Chemicals

Coatings

Cosmetics

Food processing

Our references VS 2000

Custom-made filling, labeling and packing line

Whatever your business sector or product, CDA provides the experience of its engineering design office to conceive and design your customized machine to match your requirements and constraints, regardless of whether you require a filling, labeling or integral solution

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labeling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients,

105 countries